Additional break in running diminished left side running tendency, so the habit must have been brought by tire conicity, uneven wear on tread surface dragging the effect of former bad habit. Judgement must be done after some adequate further running. Frontal total toe value has changed into 1mm(not side slip value but tire scaling) from 0mm and the consideration has much improved steering reactions, slight wondering habit disappeared and natural transition on turning action was the harvest.

I'm going to proceed to SXE10 TOYOTA Altezza final lot that has been left untouched by myself for few month, battery additional charging and thrust angle adjustment would be the tasks for tomorrow.

Almost of the time today was spent for repairing vacuum cleaner that is for family use but used for our business everyday, on last Saturday was the worst day for one hour of final stage for us because our vacuum system became out of order with sudden stop, about this long story I'll mention tomorrow.

2013年4月28日日曜日

2013年4月27日土曜日

Just below 60km/h only

An attempt was performed and done well to establish "Zero Thrust" setting under the existing axle constructive geometry in BC7 SUBARU Legacy LSi US model, but the defects in steering reaction at higher speed than 60 km/h is perceived, left side running habit as some defects expected prior to the work. It goes straight at relatively lower town speed but on the highway, the upper mentioned strange habit appears. This is the result of the temporary symptomatic treatment ignoring fundamental geometric constructive error in the axle suspension. Lower main bars should be disassembled thoroughly and reconstruction in correct position would be the following procedure as a natural story. Little time is left for me and no way to linger more, because next one, SXE10 TOYOTA Altezza is long waiting for it's alignment correction.

2013年4月26日金曜日

Zero Thrust

Finally, I have established "Zero Thrust" construction on BC7 SUBARU Legacy LSi US model before long today! 0,119 minute angle value inside of rear total toe was the result. Then how do know the critically corrected condition? Running on the flat ground surface, steering reaction sticks at one position like doing on a straight rut. This change of steering reaction characteristics occurs suddenly when all the requirement of wheel alignment and axle constructive geometry fulfilled. Nobody knows this change in physical properties of steering reaction such as a magic till the driver actually drive the very car.

The factory test drivers should know about this truth and fact with no doubt and that secret should be noticed to the consumers? I would like to refrain from writing further more----?

I feel it pity to know that almost of the produced automobiles all over the world finish their lives without exerting their ultimate capabilities of physical performances just only because of the mentioned reason.

Finally, I have established "Zero Thrust" construction on BC7 SUBARU Legacy LSi US model before long today! 0,119 minute angle value inside of rear total toe was the result. Then how do know the critically corrected condition? Running on the flat ground surface, steering reaction sticks at one position like doing on a straight rut. This change of steering reaction characteristics occurs suddenly when all the requirement of wheel alignment and axle constructive geometry fulfilled. Nobody knows this change in physical properties of steering reaction such as a magic till the driver actually drive the very car.

The factory test drivers should know about this truth and fact with no doubt and that secret should be noticed to the consumers? I would like to refrain from writing further more----?

I feel it pity to know that almost of the produced automobiles all over the world finish their lives without exerting their ultimate capabilities of physical performances just only because of the mentioned reason.

The factory test drivers should know about this truth and fact with no doubt and that secret should be noticed to the consumers? I would like to refrain from writing further more----?

I feel it pity to know that almost of the produced automobiles all over the world finish their lives without exerting their ultimate capabilities of physical performances just only because of the mentioned reason.

Finally, I have established "Zero Thrust" construction on BC7 SUBARU Legacy LSi US model before long today! 0,119 minute angle value inside of rear total toe was the result. Then how do know the critically corrected condition? Running on the flat ground surface, steering reaction sticks at one position like doing on a straight rut. This change of steering reaction characteristics occurs suddenly when all the requirement of wheel alignment and axle constructive geometry fulfilled. Nobody knows this change in physical properties of steering reaction such as a magic till the driver actually drive the very car.

The factory test drivers should know about this truth and fact with no doubt and that secret should be noticed to the consumers? I would like to refrain from writing further more----?

I feel it pity to know that almost of the produced automobiles all over the world finish their lives without exerting their ultimate capabilities of physical performances just only because of the mentioned reason.

2013年4月25日木曜日

Wheel alignment for 10 years

I had been exerting myself in establishing wheel alignment and axle constructive geometry of the vehicles. Following an officially, I had been scaling only from rear wheel toe value and it's total vector direction, correcting lateral swing. Steering centric position marked on the steering column drifts every time I changed rear thrust direction, the results of scaling value drifted as illusory target, as the later research proved that the fret had been caused by the intended frontal axle constructive design to correct and to compensate the alignment error automatically, so to speak "Self Steer Effect". Moving and drifting of the reliable position of critical reference points have been making it difficult to establish the "Zero Thrust" condition of vehicles for these 10 years. Now I have found out the means of escape from impasse that hit me!

Judging from frontal wheel total toe vector direction with my keen 6th sense while actual running, check and mark down onto steering column "2 positions", straight running position and free no assisted position. Without writing, two positions should be matched as a single point if both positions might be wobbled and drifted on the way, but remember here, the point of adjustment is not frontal axle but of rear total toe direction and it's value only, no any other adjusting point should not be moved however sweet a temptation of the devil might be.

Judging from frontal wheel total toe vector direction with my keen 6th sense while actual running, check and mark down onto steering column "2 positions", straight running position and free no assisted position. Without writing, two positions should be matched as a single point if both positions might be wobbled and drifted on the way, but remember here, the point of adjustment is not frontal axle but of rear total toe direction and it's value only, no any other adjusting point should not be moved however sweet a temptation of the devil might be.

2013年4月24日水曜日

Received lighting equipments

Chandelier decoration lighting equipments mentioned yesterday came to me as an ending of the story. So, I'm troubled where to set them effectively in my environment? Also, a rectangle shape shoes box did, but for different applications for me, as an useful tool keeping furniture beside working pit.

I have measured to put some net preventing the invasion into my garage by Tommy and Kitty, but as for my surprise, I saw a mouse running on the highest tension of the roof last night. I must consider about the method of disinfection, dirty with scattered microorganisms by them. Consultation with the Health Center might be necessary. Removing their nest and being refrain from putting around any food might the way, so I have just asked about this problem to one of a familiar carpenter.

I have measured to put some net preventing the invasion into my garage by Tommy and Kitty, but as for my surprise, I saw a mouse running on the highest tension of the roof last night. I must consider about the method of disinfection, dirty with scattered microorganisms by them. Consultation with the Health Center might be necessary. Removing their nest and being refrain from putting around any food might the way, so I have just asked about this problem to one of a familiar carpenter.

2013年4月23日火曜日

At a loss?

One of my friend in neighborhood wanted me to have a set of deck chair shown in the picture, so I accepted because some suitable place was found here. The story is lasting, in addition he want me to have more, two set of Chandeliers! I feel it difficult to refuse his proposal after receiving former one, how shall I do about this from now. He is obliged to move to new another place because of the Station Development Program dictated by the Municipal Government. And he has not enough place to accept upper items, instead he does not want to throw away to a trash heartlessly. Lighting decorations are not so small ones, so adequate space is required to put and hang with looking good. I have already one set in my storage in my villa, three of them in total, selling to some used treader might be a choice, but I don't want. I'm at a loss, how shall I do?

2013年4月22日月曜日

Anti-reflection

It took me relatively long time to finish the measure onto DIY extension tubes for Canon EOS system applying anti-reflection construction utilizing flocking Non-Reflective cloth yesterday. Considerably strong reflection light noise was observed on internal barrel concave surface as shown, it is a matter for no neglect. All the lens and camera production makers are exerting themselves in researching in eliminating the harmful barrel internal reflections before prior to the releases. Inconvenient reflecting phenomena occurs not only on the barrel internal surfaces but also on lens element, on shiny bayonet mount rear surface, on helicoid thread waving grooves, body mirror box and also on image sensor surface. Any measures for this unacceptable phenomena for the users should be done with some definite efforts if some clear and fine imaging results are desired. Consequently, did I apply some pieces of Non-reflective flocking cloth inside walls of EOS extension tubes following the concept that any factory designers do on their products.

2013年4月21日日曜日

Difficult & Tricky research

High performance tire shows bad alignment habit apparently compared with ordinal one, it's relatively easy to know the steering 2 positions on the steering column marks. One is for straight running and another is for the defined position by "Thrust Angle". This angle is formed by rear total toe vector direction and the centric of the automobile, so the bad habit is corrected to meet with latter steering position eliminating thrust angle to the ravel of zero degree as near as possible. Most of the drivers would not recognize the discrepancy because the driven car has some tendency to go relatively straight with the help of "Self Steer Effect" designed in frontal axle construction. Caster actions connected with tie rod through steering linkage, SAI(Steering Axis Inclination, same as King Pin Angle) are the main factors. Generally, self steer effect is observed when the car stops on a relatively flat ground surface, signal stopping phase for example, steering moves right and left repeatedly, this phenomena is mainly caused by thrust angle vector correction by self steer effect or requires steering action to specific direction, right or left depending on the thrust angle direction, plus or minus. And on the next phase of starting, steering action would be performed to opposite direction. This reversal steering action is caused by the changing of weighted points, anterior into hinter side. In another words, is your car is possible to stop without any assistance on steering wheel and to start straight without any touching on the steering? If there are a passenger's car driver, want I see him or her to say a great and maximum praise on earth! Because it is very difficult to establish "Zero Thrust" condition eliminating various errors in the wheel alignment and axle constructive geometry.

Also, we must remember the troublesome effect of dynamic weight distribution balance.

Also, we must remember the troublesome effect of dynamic weight distribution balance.

2013年4月20日土曜日

EOS extension tubes

As I mentioned the other day, 40mm and 80mm extension tubes with Canon EOS bayonet mount for Minolta MD Macro ROKKOR 100/4(already modified into Canon EOS bayonet mount) have completed. As commercially available iron steel COFFEE cans were utilized to form tube barrel, they are very light like nothing but enough strength and stiffness were obtained. The picture shows a comparison of 100/4 Macro lens on ordinal 1/2 magnification with both two extension tubes together with 40mm and 80mm. These equipment would open a wonderful micro magnification world for me, in addition, a genuine Minolta Focusing Rail obtained last month would play a good part in close up situations in future. Micro Photographic transparencies would appear soon. Because an important anti-reflection walls with flocking non-reflective cloth were not prepared inside of the barrel, these wanton sporting would be done tomorrow.

Precise adjustment?

Precise rear toe adjustment to change the total toe direction, "Thrust Angle", was also performed last night seeking the critical Zero degree establishment. The more critical phase I might come into, the more precision is required in the adjustment procedure. The problem of elusive variation on data sampling could not solved until the pressure on touching surfaces between the scaling point and the device should be kept evenly at each measurements. 1 kg iron rectangular solid is put aside touching beside the scaling device, I make it a rule to keep the experiment condition same at any time I do. This is the same as an electric terminal's pressure.

BC7 SUBARU Legacy LSi US model goes straight without any finger assist holding on a flat ground plane, but some residual internal stress remains in rubber material construction,in bushes also in tire treads, the evaluation of true performance should be done after 200 km distance breaking in actual running. The physical property of rubber materials is always a awkward presence, causing hysteresis and viscoelasticity.

Repeated adjustment destroyed tightening 17 mm nut, the work is done under severe condition without lifting machinery and the accessing direction is strict against my will, so this kind of error happens occasionally, as a matter of fact, it was replaced into genuine new parts.

The measure being done on BC7 now is mealy a symptomatic treatment, the result would be clear that the fundamentally accurate geometric axle construction should be establish before we proceed to wheel alignment adjustment, if we desire form a heart a perfect alignment that the steering reaction and habit does not change at any speed ranges, this is my conclusive hypothesis now. It's a fun for me if some unknown result was the same as my predictive and if not, my curiosity is amplified more and more.

2013年4月19日金曜日

Thrust adjustment

Thrust angle adjustment on BC7 SUBARU Legacy LSi US model is now undergoing, almost of it has removed but still remains a bit, probably below 1 minute angle value to plus direction. Very slight as it is, right side steering adjustment while running is required. Bad steering habit appears as a counter measure no matter how the rate of discrepancy might be only 1 minute degree. It means that the car goes left side automatically after 100m distance, in another words, the driver goes on a part of circle and he or she would adjust unconsciously the steering position to keep straight running with some subtle expectation all the time. The less steering adjustment, the better for comfortable ride if we pay attention on the fatigue after driving long. So, the diameter of the circle should be as long as possible to make the adjusting timing as less as possible. This is why I have been insisting on Zero thrust angle on the vehicle.

200 km distance on the high way running yesterday has eliminated a tight corner braking phenomena thoroughly, that phenomena has not been brought by clutch facing surfaces wear as before but because of a lack of finishing on replaced new facing parts. Consequently, my lovely BC7 has acquired some perfect trans-axle drive train with my satisfactory. Innate rear toe adjusting constructive design is not enough to adjust and to tighten so precisely as required actually, cam adjusting mechanical construction and backlash there make it rough and half-way whoever might try to do that, so much more precise and dense adjusting mechanical designing should be applied there like that of microscope focusing construction? As a matter of fact, the adjusting constructive mechanism does not play well where so precise action is demanded as to the rate of below 1,000 micrometer order revel. In order to press ahead with doing the work under some very inadequate circumstance, external precise device should be invited like LASER pointer equipped ST, so I utilize it in the scaling and adjusting procedures, also some experience and keen sense and observation with mental concentration might be indispensable in the situation.

200 km distance on the high way running yesterday has eliminated a tight corner braking phenomena thoroughly, that phenomena has not been brought by clutch facing surfaces wear as before but because of a lack of finishing on replaced new facing parts. Consequently, my lovely BC7 has acquired some perfect trans-axle drive train with my satisfactory. Innate rear toe adjusting constructive design is not enough to adjust and to tighten so precisely as required actually, cam adjusting mechanical construction and backlash there make it rough and half-way whoever might try to do that, so much more precise and dense adjusting mechanical designing should be applied there like that of microscope focusing construction? As a matter of fact, the adjusting constructive mechanism does not play well where so precise action is demanded as to the rate of below 1,000 micrometer order revel. In order to press ahead with doing the work under some very inadequate circumstance, external precise device should be invited like LASER pointer equipped ST, so I utilize it in the scaling and adjusting procedures, also some experience and keen sense and observation with mental concentration might be indispensable in the situation.

EOS extension adapter

Canon EOS mount extension adapters are under construction utilizing Canned Coffee steel bottles, 40mm and 80mm axial values are designed for emergency use of Minolta MD Macro ROKKOR 100/4 that had been modifies it's bayonet connection into EOS. Now, 1/1 or more magnification shooting would be applicable after completions. High magnified new micro world is waiting for me.

I'm going to apply Non-reflective flocking cloth inside of adapter barrel in every direction. EOS body cap and lens rear cap would be set for the connections, because Minolta Macro ROKKOR 100/4 lens weighs relatively slight, so 80 mm extension would not cause lens obey down so much. I'm looking forward to use actually in the critical situations.

2013年4月18日木曜日

On Thrust Angle in vehicle

Most of the passenger's car drivers does not have an experience to drive an automobile adjusted with "Zero Thrust Angle Wheel Alignment" including myself what I had been over 10 years ago, simply because most of the ordinary car had not been adjusted the angle value exactly at Zero Degree except some unreasonably expensive ones like PORSCHE or FERRARI with small productions.

The results of conformity between the human 6th sense of center and that of the vehicle driven by the driver is not perceived actually because of no experience.

One of an European Motor Vehicle Safety Standard specifies the discrepancy tolerance value should be set between plus 10 minutes and minus 10 minutes, so the Thrust Angle of new cars are so adjusted on the factory construction lines before putting in the show rooms to meet with the standard specified by the regulation. On the other hand, is there any specification on Thrust Angle Value in our country Japan? The answer is "Not!" as we know, we do not have such an critically and indispensably important inspection item both in Road Traffic Act and in Road Trucking Vehicle Act. Though following descriptions below are based on my own imagination, this strange phenomena might be caused by some adhesion between government's contemplation and vehicle manufactures who want cost reduction or just a negligence by someone else? I had an opportunity 3 years ago to peep into an internal confidential document in VW AG Japan, by the way, the specification on the thrust angle tolerance had been remade into plus minus 20 minutes in spite of the value is done at 10 minutes in Europe? Why 20 minutes only for export to Japan? Do we Japanese Nation are looked down on by Germans because of Asian Yellow Nation? Why do VW company makes little of us so much, on of an important Ally of former WW2 in far East Orient? If I interpreted in good reasons, relatively slow traffic as we have that never exceeds 100 km/h, discrepancy between 20 minutes might be enough and Japanese Government also have the same perception?

The results of conformity between the human 6th sense of center and that of the vehicle driven by the driver is not perceived actually because of no experience.

One of an European Motor Vehicle Safety Standard specifies the discrepancy tolerance value should be set between plus 10 minutes and minus 10 minutes, so the Thrust Angle of new cars are so adjusted on the factory construction lines before putting in the show rooms to meet with the standard specified by the regulation. On the other hand, is there any specification on Thrust Angle Value in our country Japan? The answer is "Not!" as we know, we do not have such an critically and indispensably important inspection item both in Road Traffic Act and in Road Trucking Vehicle Act. Though following descriptions below are based on my own imagination, this strange phenomena might be caused by some adhesion between government's contemplation and vehicle manufactures who want cost reduction or just a negligence by someone else? I had an opportunity 3 years ago to peep into an internal confidential document in VW AG Japan, by the way, the specification on the thrust angle tolerance had been remade into plus minus 20 minutes in spite of the value is done at 10 minutes in Europe? Why 20 minutes only for export to Japan? Do we Japanese Nation are looked down on by Germans because of Asian Yellow Nation? Why do VW company makes little of us so much, on of an important Ally of former WW2 in far East Orient? If I interpreted in good reasons, relatively slow traffic as we have that never exceeds 100 km/h, discrepancy between 20 minutes might be enough and Japanese Government also have the same perception?

2013年4月17日水曜日

Difficulty in wheel alignment adjustment

Generally writing, the wheel alignment procedure would never finish after single attempt, because of physical property in rubber materials set everywhere in axle construction. As we know, rubber has an innate property to remain distortion that is influenced by hysteresis phenomena, most of the distortion comes back as it was, but a slight initial strain residual stress remains. Checking, adjusting and actual running break in steps are repeated in order to minimize the discrepancy and to narrow the acceptable tolerance, this is why the establishing wheel alignment and axle constructive geometry. As a primitive attempt, I will try to adjust thrust angle(the direction of rear total toe) without any fundamental correction, let's see what will happen, probably, quire strange steering reaction habit would appear and disappear that the rate of tendency drifts occasionally on the speed and driving phase. Some datum would be obtained. Now BC7 SUBARU Legacy LSi US model is under operation on it to form the figure of ultimate.

Though he refused to receive the half amount of payment for painting on air-cooled VW 1302 Super Beetle, I dare gave it to him with the intention of starting the work. He called up me to ask where the Vehicle inspection certificate has tucked away, so I replied, under the navigator's seat it is. Probably, it would take period of time as long as 30 days from now, or more? I promised with him that no complaint would be declared if he did anything necessary had done without any financial stress. I'm looking forward to see my mechanically best conditioned new look Super Beetle with original color Marina Blue painted.

Though he refused to receive the half amount of payment for painting on air-cooled VW 1302 Super Beetle, I dare gave it to him with the intention of starting the work. He called up me to ask where the Vehicle inspection certificate has tucked away, so I replied, under the navigator's seat it is. Probably, it would take period of time as long as 30 days from now, or more? I promised with him that no complaint would be declared if he did anything necessary had done without any financial stress. I'm looking forward to see my mechanically best conditioned new look Super Beetle with original color Marina Blue painted.

2013年4月16日火曜日

Moving

I found out miserable scenery that almost of flower trees had been cut down and killed permanently on earth! They were all indispensable parts of our lives to be enjoyed for a half of century period of time. Just we feel sad to see that, no possibility would be desired to bloom on every spring season from now! Though this kind of victims might be there under the beautiful name with the just cause of Station Development, unacceptable melancholy does exist in our minds.

Careful checking and measurement on wheel alignment and axle constructive geometry on SUBARU BC7 Legacy LSi US model proved that there exist some discrepancy on frontal main bar finishing onto the body causing plus 1,74 minutes(angle value) set back on frontal axle. Loosening the attachment bolts and correcting in the position of frontal main bar is necessary, also not only setback adjustment but also establishing lateral displacement is indispensable in the procedure. Frontal wheel alignment would be re-established from the beginning after that. Complicated and tiresome muscle work as it would be, I have a good will and intention to carry it out, because I could imagine that I would drive this first generation SUBARU Legacy with a biggest pleasures in future.

By the way, a critical question occurs in my mind that had been sticking in the corner of my brain.

As I have perceived the effect of the displacement of frontal knuckle position after some experiment, so important to fix them in correct positions are indispensable to obtain a good ride. Most of the B segment passenger cars invite movable compliance bushes on frontal lower arm's hinge positions in order to obtain better ride with compliance, also rear torsion bar axle construction has the same, then how is the comparison with my opinion here?

The contradiction might be a hidden reason to have given up my Yaris a month ago that had not any defect but in best condition.(With frontal lower arm compliance bush, also torsion beam rear axle construction for the rear main hinge compliance bushes)

2013年4月15日月曜日

SUBARU Legacy BC7 LSi

Any problem caused by mechanical defect or error would not be solved before it is corrected or repaired fairly however long it is used with enduring inconveniences, better expectation, prayer, devotion nor curse would not take effect if any or many specific religions might be devoted. Just watching or waiting without taking any measures, especially correction and establishing in the wheel alignment and fundamental error in geometric construction in axle suspension mechanisms require tremendous efforts and precise concentrations with patience, so we do not get in other(even professionals) leaving to others.

Describing like this, it is a shame to write that, considerable set back value was found in my lovely BC7 initial generation Legacy sedan US model, the discrepancy value prevent me from proceed to next step, so, measuring step only is the task today. Remembering the past, this is my selfish mistake to make it run to the right to cancel the left side run habit, but my later research proved that the measures to makeshift like this is nothing but more hustle than it is worth and the cheap trick is consumed by the caster action, self adjusting and correcting caster actions on both side, so to speak "Self steer". As a matter of fact, it was not canceled in pieces, strange bad habit is illusory with glimpses changing the rate and sometimes even to the opposite direction depending on the speed ranges. It's a matter for regret that this car has been used in ill alignment condition as long as 130,000 km distance, also it was an unfortunate situation for this model. Now, I have made up my mind to secure this with all my efforts from now. Eliminations of Set back, lateral offset on front and rear main bars, swung rear end and establishing wheel alignment on the former geometric construction are the indispensable requirement to drive in comfortable condition, this is my principle in my automobile maintenance. It's a good opportunity to do that, because VW 1302 Super Beetle is absent from my garage because of getting face lift(body painting in the original color, Marina Blue).

Ground plane for measuring and adjusting the wheel alignment and constructive axle geometry was re-checked so carefully as not to have any regret, because the parallelism and flatness of ground surface is the key to rely on and the obtained datum in future are fully based on the critical plane, horizontal and also vertical directions. So, I cannot be too careful to ascertain the accuracy of the reliable plane repeatedly and occasionally.

2013年4月14日日曜日

Proceeding

Thanks to my own desperate effort last late at night on the steering gear box for air cooled VW 1303 Super Beetle, these steering replacement parts would be kept so long from now, these kind of parts, especially the gear box is not available in the world wide market as a replacement parts, specific right side steering design for few countries with left side traffic law is the reason, Japan, England and Australia and so on. Remembering that the best care must be taken while finishing worm gear surfaces, exactly the same surfaces between input and output gears must be touched on every trial fitting phase, no any angular positioning discrepancy is accepted, again exactly the same opposing surfaces should touched each other, so precise and fine finger works using some diamond files with ultimate concentration under keen sense is required. The very professional skill like a watch maker is indispensable. In short, difficult work marked with 5 wrenches.

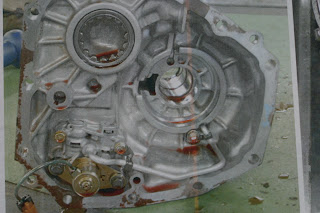

As for the replacement of rear automatic Multi Plate Transfer 5 disks done by OSAKA SUBARU Yao branch, the works had been finished without delay, though some interfering accident happened on the way. A necessary step to remove exhaust intermediate pipe, 3 of the stud bolts were all broken in loosening phase because of rust with long period of time, for 20 years. This problem was solved as an usual manner making hole through and stainless bolts and nuts were applied there as a measure. This required process was the first experience for them, because the flange parts there have not been set on the same kind models on Japanese domestic one but only for US model was the reason. As the trans-axle supporting rubber mounts on right and left were replaced at the same time for the sake of disassembling the rear trans-axle case, some motor vibration while idling has increased, it's probably caused by less compliance because of new rubber material's harder viscoelasticity, the phenomena will be soon improved and eliminated after some period of use. Judging from the condition of included ATF, no bad signs such as clutch plate burn or excessive wear would not be caused inside of the main JATCO 4 Speed Trans-Axle itself.

One of the person served SUBARU factory in Research and Development division says about the first generation BC models that a lack of frontal caster value might the reason for unstable straightness and this is the critical disadvantage for the model. But, I don't think so with different evaluations, because the vehicles designed with much less caster value has enough stability, for example, air cooled Super Beetle with no steering power assist, so on this proposition, deeper considerations, more precise scaling and adjustment on wheel alignment and fundamental geometric axle construction checking would be done on BC7 SUBARU LSi US model as a residual task on this initial Legacy model with left side steering constructive design.

2013年4月13日土曜日

Unusual affair

Fine this morning as it is, not a small Earthquake happened soon after dawn in Kinki area must have brought uncountable influences, Hankyu Rail Way Kobe line was stopped, probably all lines? Their operating diagrams this morning must have been destroyed completely. The origine of the quake is the same as Big disaster of Hanshin Awaji, that obliges me the perception, never happens again at the same place because the stress has been released. So, I changed my to take train to come to my working place by car, SUBARU BLE 3L model. Though some traffic clouding way imagined, I could arrived to the destination without delay. We should realize again that we are far from controlling Nature, the power of it is far beyond to our imaginations.

A steering gear box equipped in air-cooled VW 1303 Super Beetle was fully disassembled last night to confirm the criminal that has been causing some clicking reaction on the specific operating way. Careful checking on the touching surfaces revealed some unnatural shinny portion at the specific inner circle end, probably this uneven wear should be the reason for the chronic clicking reaction. The criminal would be constrained after checking by painting the surfaces and assembling both of the worm gears with actual operation, reporting later about this procedure. In addition, not a little amount of granular hard dust were recognized in the lubricant, they might be reason for the inconvenience? Shining point is observed on the opposing surfaces in both in and out worm gears. Such kind of problem under less quality control must have caused in the production line at that time, to whom shall I complain on this phenomena? But, as to my surprise, the surface of one piece finished input worm gear piece was processed by means of TAFT riding process coating technology, we didn't have such a sophisticated way at all over 40 years ago, I appreciate German industrial development at that period of time. Anyway, I feel that I could find the way to solve this problem on the steering gear box with a fair amount of certainty.

2013年4月12日金曜日

Discrepancy

Though a proverb says, repeating the atmospheric temperature warm and cold finishes at the timing of equinoctial week, but cold weathers are lasting these days just below 10 degree celsius. Computer controlled automobile must adopt the mixture in this cold weather according to the signals from cooling liquid temp sensor, outside air temp. sensor. But my VW air-cooled 1302 Super Beetle relies just on the automatic but mechanical choke module condition with coil bi-metal heater construction that requires a bit rotating adjustment.

SUBARU BLE B4 Legacy 3L model here wears different wheels and tires from it's original design, those of BRZ has different off-set value, 55 to 48, this 7mm discrepancy causes problems, some quire strange steering reactions, feeling caught in initial rising phase, lack of linearity in action and an mission of the steering pressure, very strange on earth! This must be caused by the change of scrub points on the tread surfaces especially on the front wheels. Remember that the scrub point is very important to have been established by the factory designers and engineers, of course by many experiments by the test drivers based on their accumulated know-hows. So want I shout with loud voice to my son, never change a fundamental axle constructive geometry whatever reasons you might have! (Probably you would turn a deaf ear to me?)

Do you think it looks better if the tire outer surface exists on the same plane of body fender by changing wheel off-set value in spite of causing incredible inconveniences? Then how about tire burst dangers touching with body wheel arch in addition to the upper inconveniences? The importance is not the balance between tire and body vertical plane but the fundamental geometric axle construction, don't you think? Before that, you can not see your car's appearance while you are driving? You can not ignore any laws in Physics, you are not a Scientist, aren't you?

What makes you take pride while you are in the car and you are driving it?

There must be some misunderstandings? Do you have a perception that

you are not a so great person as to you feel on yourself, because it is not designed by you nor was not constructed by yourself nor was not sold only for you, just you are driving it by steering, lever and pedal action controls.

Most of a car driver might feel pleasant if his or her car was praised as good car, but an additional sentence, "Not you but this car." would makes the person feel bad, angry sometime quarreling. I don't know why, just I'm talking about the truth and the fact?

SUBARU BLE B4 Legacy 3L model here wears different wheels and tires from it's original design, those of BRZ has different off-set value, 55 to 48, this 7mm discrepancy causes problems, some quire strange steering reactions, feeling caught in initial rising phase, lack of linearity in action and an mission of the steering pressure, very strange on earth! This must be caused by the change of scrub points on the tread surfaces especially on the front wheels. Remember that the scrub point is very important to have been established by the factory designers and engineers, of course by many experiments by the test drivers based on their accumulated know-hows. So want I shout with loud voice to my son, never change a fundamental axle constructive geometry whatever reasons you might have! (Probably you would turn a deaf ear to me?)

Do you think it looks better if the tire outer surface exists on the same plane of body fender by changing wheel off-set value in spite of causing incredible inconveniences? Then how about tire burst dangers touching with body wheel arch in addition to the upper inconveniences? The importance is not the balance between tire and body vertical plane but the fundamental geometric axle construction, don't you think? Before that, you can not see your car's appearance while you are driving? You can not ignore any laws in Physics, you are not a Scientist, aren't you?

What makes you take pride while you are in the car and you are driving it?

There must be some misunderstandings? Do you have a perception that

you are not a so great person as to you feel on yourself, because it is not designed by you nor was not constructed by yourself nor was not sold only for you, just you are driving it by steering, lever and pedal action controls.

Most of a car driver might feel pleasant if his or her car was praised as good car, but an additional sentence, "Not you but this car." would makes the person feel bad, angry sometime quarreling. I don't know why, just I'm talking about the truth and the fact?

2013年4月11日木曜日

Disassembled gear box

All the complicated works have thrown away to professionals promptly this morning, so my main garage is now unusually empty. Sitting here makes me feel some loneliness and regret that I escaped from the works that could be done myself, deserting them in need to help also disobeying my own principle that all that I can do should be done myself. My aged body condition as a geriatric would be a good way to apologize on these events.

Results of the inquiry to FLAT FOUR Kyoto branch about the parts supply after body painting of VW 1302 Super Beetle, it has cleared that all the rubber parts and moles are available without any fears. So, repainting work would proceed under relief from now.

About the spare parts of steering gear box, a wrench was so adjusted to adopt onto rock nut diameter and I have succeeded in loosening it safe. After several consideration found I a special tool to remove taper roller outer lace adjuster part, just gear box control arm locking nut was suitable for the purpose as shown in the picture. Though crisp phenomena disappears if it is loosened, that inconvenience might caused by the taper bearing defect or worm gear fitting input and output, I checked by loosening 4 of 13mm gear box bolts and input shaft was rotated with finger action. Then no friction occurs how ever tightly the in-put shaft supporting taper bearing might be closed. The conclusion is fitting between two worm gears input and output. Probably gear surfaces galling would be imagined, in the worst case, mirror finish taking a lot of trouble by myself with diamond fine files after some electric welding on the defect in the real. This kind of measure is the first experience for me, I'll do that as a good opportunity to have an experience, because have I a good professional friends here and there, have a way to overcome this kind of hardship. Do I have some confidence to do that? Yes, I do!

2013年4月10日水曜日

Revolution

It's colder than usual, the cold air mass from China main land coming to Southern direction covering OSAKA is the reason, so I'm in a winter wear jumper this morning. Best care should be taken this season not to catch cold, as for diseases this season, those of virus-derived are reported on the radio news. In the relations with them, I must study back on Immunology again because Avian influenza and Rubella, both of them are caused by virus promptly and dangerous and harmful diseases to human-being would come to fatal when it comes to severe symptoms. By the way, virus is not a living thing but is considered to be a different existence from bacterias. More over, we can continue our lives because our internal virus programmed genome could win continuous battle with externally invading virus.

I have determined to have VW 1302 Super Beetle body painted by the professional painter that I know well and BC7 SUBARU Legacy LSi US model's rear transfer clutch(MPT) replaced by OSAKA SUBARU dealer, because of my unfavorable health condition. Of course I know that the escaping behavior like these might be some regrettable memories remembering later, those tiresome works would not proceed if there is no resignations now. Probably the works would be left undone till their lives end. The sooner the better, I'm ready, so, Super Beetle would be brought to the painter's today and BC7 SUBARU Legacy LSi would be done on this Thursday.

I have determined to have VW 1302 Super Beetle body painted by the professional painter that I know well and BC7 SUBARU Legacy LSi US model's rear transfer clutch(MPT) replaced by OSAKA SUBARU dealer, because of my unfavorable health condition. Of course I know that the escaping behavior like these might be some regrettable memories remembering later, those tiresome works would not proceed if there is no resignations now. Probably the works would be left undone till their lives end. The sooner the better, I'm ready, so, Super Beetle would be brought to the painter's today and BC7 SUBARU Legacy LSi would be done on this Thursday.

2013年4月9日火曜日

Steering link shaft

Once deserted steering link shaft parts with universal cross joint on both side for VW Super Beetle was checked again on the defected portion. The mechanical designing shows needle roller bearing but with rust inside. As the diameter value of the needle was 1,45mm, I have determined to replace it into another needles with 1,65mm diameter and with 6,80mm axial length. Probably the original value must have been 1,50mm, rusting phenomena made them thin and smaller. 19 pieces were acceptable between the space(former 18 pieces), after applying chrome molybdenum grease sealing cap was set on place by means of an oil pressure pressing machine. As a matter of grad, no backlash was felt after reassembled, so this steering shaft linking parts with two universal joints would be kept as a useful replacement parts.

2013年4月8日月曜日

Super Beetle in a good mood

Combustion note of air-cooled VW 11 motor sounds me so comfortable as I had adjusted valve clearance firmly at the standard value of 0,150 mm the other day and also mixture control was adjusted a little bit leaner, but cold morning as it is today, still a bit richer condition now. As for backlash in steering linkage, the tightened gear box adjuster well contributes to establish desired straight running stability. I mentioned before about the inconvenience in the spear gear box parts that had critical wear on the strict cross shape connection in steering universal joint, so, careful checking is necessary also on the same portion of my 1302 Super Beetle, because that point is always exposed in outside air, some lack of lubrication is imagined? Some stingy idea comes up in my mind, even a worn universal joint parts may survive again if the worn space might be compensated by a piece of thin metal plate that is utilized from any spiral thin ribbon spring plate made of hard iron plate, just the elimination of backlash is important, no?

As a conclusion today, all the mechanical moving parts should be lubricated adequately all the time to avoid inconvenient wearing and friction resistance loss, to prevent rusting.

As a conclusion today, all the mechanical moving parts should be lubricated adequately all the time to avoid inconvenient wearing and friction resistance loss, to prevent rusting.

2013年4月7日日曜日

Storm last night

The storm last night past but the weather condition is not favorable this morning. Judging from the weather map, unusual condition had been brought by separated low pressure North to South being mischievous so much. It rained cats and dogs and our feet were drenched to the skins. The atmospheric instability remains also now in the morning.

I was in Namba at Southern Osaka city called "Minami" with my few friends taking supper together with them. Red-light district has been influenced by the recession, as a matter fact, the bar we visited was occupied only by our group.

As a conclusion last night after some conversations, our residual lives, probably within 20 years, should be lived with pleasure avoiding things unpleasant under health body conditions. In order to accomplish that way, some adequate athletic training repeating every day is indispensable, that was our one accord as medical professionals, also we should refrain from too much eating and taking less food at least 2 hours prior to going to bed. Chronic Muscle Stiffness especially in neck, back and hip would be the good reason for every cardiovascular disease, because our body cells could live in good health only with good fundamental body liquid circulation keeping the balance of electrolytes in relationship of the pulse.

I was in Namba at Southern Osaka city called "Minami" with my few friends taking supper together with them. Red-light district has been influenced by the recession, as a matter fact, the bar we visited was occupied only by our group.

As a conclusion last night after some conversations, our residual lives, probably within 20 years, should be lived with pleasure avoiding things unpleasant under health body conditions. In order to accomplish that way, some adequate athletic training repeating every day is indispensable, that was our one accord as medical professionals, also we should refrain from too much eating and taking less food at least 2 hours prior to going to bed. Chronic Muscle Stiffness especially in neck, back and hip would be the good reason for every cardiovascular disease, because our body cells could live in good health only with good fundamental body liquid circulation keeping the balance of electrolytes in relationship of the pulse.

2013年4月6日土曜日

SUBARU E-BLE

The weather conditions today and tomorrow would not be favorable at all, because of low pressure developing rapidly in Southwestern portion of Japan main land, very unstable atmospheric condition would be imagined, it would seem like a Typhoon, so I should refrain from going outside tomorrow. Cherry blossoms everywhere would be run amuck on earth, it would be a matter for regret.

A pilot of airplane never takes off before checking all the operations, oil pressure, cylinder temperature, another electric device conditions and moving parts of every wing, otherwise the plane would be in fatal condition once it goes up in the air. Following the manner I make it a rule to check my automobile engine room before starting as everyday opening operation, also this procedure is stipulated in the Road Vehicle Act in Japan.

Though it may play a part of noise insulator, all the unnecessary decorative plastic covering parts were removed thoroughly for my use of this automobile. I pay much attention on the safety of the machine rather than aesthetics there, before that the engine room is not always shown while driving, because the bonnet part is close firm? Anyway I did it with a little complaining this morning. The constructor might be obliged to sell off their products without regards to appearances if the result might be getting in the way of actual serious use. Unreasonable opinion of the propaganda department might have been through at that time. All the removed original leather seats were replaced in the original position safe.

It took me a little time to replace the power steering pump fluid, because I didn't apply enough amount of fluid at first reading to cavitation phenomena, but now favorable at all. No defect everywhere on this BLE 3L model is observed, however this is used 120,000km already.

Six cylinders Boxer Flat motor is some good mood driving after 3 years absence, I may continue this car if my son might have determined to desert this. STI designed and produced short and hard suspension springs would be replaced into the same genuine one for Ri 2L NA model with softer axle design, I happen to keep the parts, shock absorbers and coil springs as replacement parts, they would survive and play well. Also the third party made strut tower burrs for front and rear would be removed to establish and revive originally designed totally correct compliance.

Nevertheless, how many sophisticated factory engineers had taken in the planning and how much effort were exerted there to advocate this 3L 6 cylinder AWD model few years ago, remembering the past over 60 years ago, they are all descendants of Nakajima Military Airplane Company in Tokyo?

登録:

投稿 (Atom)