2014年2月27日木曜日

Carburetor adjustment

Bench testing of two motors, OS 25LA and OS 32F with pressure nipples for YS fuel injection system proved the opinion by Mr. Yamada in Aichi Pref. was to the point, as a matter of fact, making the drum type lower throttle hole a bit opened in order to idle mixture richer was scientifically correct. The idling rotation is very stable without any symptoms of motor stop. Let's see what will happen if the motors were actually installed onto the airplanes.

I know that not a few users had thrown away the YS pressure injection system already because of unstable transition from idle to middle speed. Motor stop phenomena happens if the pressure regulator adjustment should be incomplete. I have often come across with such kind of situations, not a few airplanes were destroyed because of the system malfunction.

As for myself, I have ever been living with YS system as long as 20 years, so I have no hesitation to invite this one to my small airplane if the main needle reaction might be so peaky and troublesome to seek the best angular position.

The key to success and mastering this system is the adequate regulator angular position, there are several ways to know the terminal position to start and to adjust.

Remembering the past, this procedure to fix the regulator angular position resembles that of idle mixture screw in the fully mechanical old WEBER 40 DCOM carburetor for a sporty automobile, Talbot PEUGEOT 205 Rallye homologation model had that twin carburetors, had I been keeping it over ten years. And I would often visited in this 205 Rallye model Land Transportation Office for 2years continued regular inspection held by Authorities.

Throttle valve modification

An application of additional shnyure port in OS 25LA cylinder brought several changes in combustion state, inviting powerful rotation 12,100 rpm with Graupner 9-5 prop under K&B 500 fuel taking along vigorous vibration, but is within tolerance. Apparent improvement of combustion efficiency was observed. In order to eliminate 3 dimensional vibration adequately, several trial experiments should be performed utilizing mechanical vibration tachometer gazing at trembling directions though the method might be so primitive now a days, re-balancing of the counter weight is performed like this even in the manufacturer's research and developing division.

Some lean mixture at idle speed of 25LA on the testing bench reminds me of the very important advice 30 years ago done by the former representative of Yamada Industrial Company at Inuyama City in Aichi Pref, the lower throat of the drum type throttle valve should be slightly opened because of lean mixture compared with the condition of natural aspiration carburetor, YS regulator controls only at middle speed and the slow speed mixture should be established promptly. In another words, very accurate and perfect balance of the drum throats upper and lower throat comparison could eliminate complicated mixture control and adjusting at idle speed in the carburetor construction. Careful checking on this important point, the fact was revealed that all of the genuine YS motors has throttle valves so designed as he had said to me.

Though I do not know he is now alive or not, hope I he is still now in our world, because we have a lot of fond memories. Now, the company has been finished the change of generations, his sun is inheriting the company.

Anyway, the bench test of modified carburetor in 25LA would be performed fairly after such modification on the throttle valves, I'm sure that the experiment would obtain favorable result.

By the way, the main needle valve for natural aspiration design makes it difficult to control and adjust precisely, dull angled needle shape makes it too sensitive and too keen to adjust it in NA fuel supply condition, only one click changes the mixture ratio effusively, but it is not impossible, within my tolerance at all.

Once obsessed by the attractive interests and curiosity of the internal combustion motors, it is very difficult for me to withdrawal from it.

Some lean mixture at idle speed of 25LA on the testing bench reminds me of the very important advice 30 years ago done by the former representative of Yamada Industrial Company at Inuyama City in Aichi Pref, the lower throat of the drum type throttle valve should be slightly opened because of lean mixture compared with the condition of natural aspiration carburetor, YS regulator controls only at middle speed and the slow speed mixture should be established promptly. In another words, very accurate and perfect balance of the drum throats upper and lower throat comparison could eliminate complicated mixture control and adjusting at idle speed in the carburetor construction. Careful checking on this important point, the fact was revealed that all of the genuine YS motors has throttle valves so designed as he had said to me.

Though I do not know he is now alive or not, hope I he is still now in our world, because we have a lot of fond memories. Now, the company has been finished the change of generations, his sun is inheriting the company.

Anyway, the bench test of modified carburetor in 25LA would be performed fairly after such modification on the throttle valves, I'm sure that the experiment would obtain favorable result.

By the way, the main needle valve for natural aspiration design makes it difficult to control and adjust precisely, dull angled needle shape makes it too sensitive and too keen to adjust it in NA fuel supply condition, only one click changes the mixture ratio effusively, but it is not impossible, within my tolerance at all.

Once obsessed by the attractive interests and curiosity of the internal combustion motors, it is very difficult for me to withdrawal from it.

2014年2月24日月曜日

An accident!

Too low temperature outside invited several problems for Rooky10's flight early in the morning yesterday. As a matter of fact, it was obliged inevitable emergency landing not on the run way but on the vegetable garden near by, the damage at that time was not so much as imagined. Plowed soft soil must have reduced the damage, in addition, the weight of Rooky10 is below 1kg. 2 degree below zero celsius affected on atomization of fuel alcohol and the activity of batteries for both Tx and Rx resulting motor stop and loosing control from 100m distance. I knew after that a digital camera cannot work around 2 degree because of the physical property of Nickel-hydrogen battery. A plane crash has never been experience for these 30 years, I fee like myself a beginning layman in this field if I fly a trainer airplane?

As a revenge of this accident, I made up my mind to make a Shnurle scavenge port that lack in 25LA cylinder. Brass material of the cylinder made it relatively easy to engrave additional port on the adequate portion and much more efforts were required to engrave it's gas way in the crank case inside. Opening timing of newly prepared Shnurle port was the same as existing side ports. Test running would be performed soon.

As a revenge of this accident, I made up my mind to make a Shnurle scavenge port that lack in 25LA cylinder. Brass material of the cylinder made it relatively easy to engrave additional port on the adequate portion and much more efforts were required to engrave it's gas way in the crank case inside. Opening timing of newly prepared Shnurle port was the same as existing side ports. Test running would be performed soon.

2014年2月22日土曜日

Improved VW1302 Super Beetle

From the beginning I have been setting my heart on the performance of the old VW air-cooled 1600cc Boxer motor does not run at higher rotation because of OHV design that might invite some hesitation to gain higher rotation, but an improvement on ignition constructive design just applying semiconductor in the in the primary coil circuitry proved my selfish consideration was completely out of focus. The transient property to higher rotation is comfortable enough to satisfy myself! In another words, the character of my VW1302 Super Beetle has completely changed from dull and lazy boy into a young crisp Parisian, how come?

On the other hand, an energetic motor transformed by newly invited semiconductors in the ignition system revealed some lack of potential in the axle constructive design that has too movable and soft rubber bushes. Anyway, the principle that the total balance is indispensable at all, any reinforcement on one part in the vehicle design causes some destruction of the originally designed total balance, realized I again this fact last night.

On the other hand, an energetic motor transformed by newly invited semiconductors in the ignition system revealed some lack of potential in the axle constructive design that has too movable and soft rubber bushes. Anyway, the principle that the total balance is indispensable at all, any reinforcement on one part in the vehicle design causes some destruction of the originally designed total balance, realized I again this fact last night.

2014年2月21日金曜日

OS 46LA port timing

The bulged shape on OS 46LA's crank case for Schnurle scavenging main port shows the possibility to make additional port by myself. Schnurle ports were were examined precisely setting a comparison criteria on YS 45 SR motor's design, because I believe in YS superb performance as a reliable competition power. Observations show that the timing of Schnurle side ports are exactly the same but exhaust port opening timings were considerably different each other, this is because of prerequisite conditions of use, the former a normal muffler on the other hand the latter a tuned pipe. Anyway, in order to make up OS 46LA to a competition motor like YS 45SR, some desperate efforts would be required, engraving gas passing way Schnurle main port in that crank case and doing main Schnurle port on the closed cylinder. As I hope to see what will happen after a modifications on 46LA motor, this work would be performed relatively soon.

2014年2月20日木曜日

Maintenances

Fully mechanical Vocar 34PICT3 carburetor in VW1302 Super Beetle was readjusted following to the principle of it's designer, both bypass screw 2and 1/2 turn counter clockwise and air volume control screw also 2 and 1/2 turn to the same direction. Stable throttle actions were obtained after the work this morning. I have realized again the importance of setting the reference angular positions prior to the starting, any guesswork that needs precise adjustment could not bring good results, we should respect and admire the intent of the designer of this carburetor. Improvement of the combustion due to applying Semi-Transistor ignition system taught me how I did it imperfectly for these 3 years as a matter of fact. Probably, unfavorable fuel consumption would be improved also.

I have 2 another carburetors for Beetle as spear part, 2 distributors and 2 ignition coils. I lack spear one of mechanical fuel pump? I must prepare it sooner or later, because the fracture of diaphragm rubber means critical stuck.

The inner door handle destroyed by my mistake was repaired thoroughly by adhering the portion utilizing the material, Autopolymerizing Acrylic Resin as a additional reinforcement structure. Though, I hated the using quality with old sense of really old half broken automobile because of hanging out handle, all the bad habit disappeared after that except the inconvenience of right rear door lock actuator pin fracture. All the machinery should be continued with love on it and with some admiration to the machinery designers, because all of them exerted desperate efforts to design serving our field with good operations intentionally.

20 years long used Digital Multi Tester was disassembled and maintained on the sliding contacts inside. LR44 cell batteries also replaced into new ones, original performances could be re-obtained again after that. Development of tools and devices are also an important task for craftman in the world.

2014年2月19日水曜日

Cute Jill VW1302

Thanks to the application of DIY Semi-Transistor ignition system, VW 1600cc air-cooled AD motor was back to innate life. Though I have been obliged to regard some hesitating character of the OHV motor as an inevitable physical property of original designing, the clogged transition adjacent to high rotation was caused by the primary contact & break point terminal following-up on Earth. I know that there are many negative opinions by some professional engineers in Web site, but as for my experiment, favorable results were obtained, the primary signal into the coil that is clean enough to establish an astringent spike strained the inconvenient and unnecessary noises by the semiconductor circuitry brought an very important benefit, very easily discerned the mixture condition, rich or lean not only at idle speed also transition phase and highest speed rotation. Very comfortable feeling while accelerating phase is obtained I have been giving up to ask on this OHV motor. The tendency to motor stall immediately after the automatic choke system stops was disappeared. Now, my 1302 Super Beetle has become my cute Jill without any bad habits at all.

2014年2月18日火曜日

Semi-Transistor ignition system DIY

Considerable contact points surface wear in VW 1302 Super Beetle obliged me to think over about some modification on ignition system, though I make it a rule to keep it's pure original condition. Seeking in my junk box, found out I NPN Transistor C1137 , a piece of diode and 120 ohm cement resistor, so no consideration interrupts me to try as an experiment. Not a few minutes were necessary to realize me an amazing improvement motor response compared with original lazy condition, after some barrack wiring of the junk parts and the system application into 11AD engine room, as a temporal setting on the cooling fan case surface. About the necessity of a heat sink for power Tr, heating amount was not not so apparent as imagined, so adhering a small piece of aluminum plate must play a good part of the purpose.

Writing the truth, 2 pieces of C5352 were prepared already for Semi-Transistor Ignition system DIY, initial barrack wired system would be used for the time being as an experimental trial.

The improvement in this trial setting must be brought by the semiconductor character of spike noise regulation, so fine signals are oscillated in the primary coil resulting strong sparking on every distributed plug.

Both idling and high speed rotation performances are excellent that has not been experienced before.(Written yesterday)

DIY semi-transistor ignition system for air-cooled VW 1302 Super Beetle was remade finally as shown in the photo, 2 pieces of C5352 PNP Tr. were applied and regular heatsink also. Care must be taken of the use of this Trip. because the Emitter terminal is connected with holding plate inside, so some isolating method should be considered. Upside down setting could carried out the purpose. All the AD motor performance was improved eye-openingly and carburetor mixture and idle valve setting were required including ignition timing. Negative opinions are observed here and there in Web site, but actual application of the additional circuitry shows incredible differences at all. Probably, this changing of phenomena must have brought by the semiconductor's effect of fine cutting on spike noises after it's on and off actions.(Heute)

2014年2月14日金曜日

Carburetor mixture control

We had cold sleet this morning in OSAKA today and Vocar 34 PICT3 carburetor in air-cooled VW Beetle 1302 was obliged to adopt the fuel-air mixture onto cold season, make it richer with turning mixture control screw(lower and smaller one) clockwisely 1/16 turn and idle speed control big screw counterclockwisely 1/8 turn. Spark advance is set at BTDC 10 degree as many owner's of Beetle do. I have never changed till now from hot Summer setting to cold Winter one. Scientific Physical Property that in the very cold condition, motors require richer fuel supply is exactly the same as model motors. In order to adjust the mixture by human capability according to the change of atmospheric condition, we should have an indispensable capability to know the actual mixture ratio immediately encountering the scenery of inconvenient motor in bad conditioning. Judge!, rich or lean now. This is a key to establish the most suitable mixture control from idling to maximum rotation. In the Radio controlled Model Airplane field, I have very often seen that Laymen destroyed their important self-fabricated airplane at the first flight because of lack of motor conditioning especially in the carburetor mixture setting. Even some factory young engineer shows unnatural correspondence at the flight site? Long nourished experiences might be required to make an appropriate reactions on to a carburetor setting and adjustment?

As an another story, I'm intending to modify OS 46LA motor into a pressurized fuel injection equipment applying the same YS pressure regulator component as done on 25LA and 32F. As I am doing to use in some eccentric way pulling out the surpassed capability of the original designing with big throat and pressurized fuel supply. Probably, additional digging of the 4th Shunyure port by myself might be required like an upper model FX46. The difference between them are the existence of crank shaft supporting bearings, but the use of the rotation around 11,000rpm would not make any physical difference? The lighter weight and the release from troublesome bearing maintenance would be convenient for me. Tuned silencer pipe is one of a choice for this 46 motor, this NOS motor would show remarkable performance in Sutkoi 40 maneuver airplane.

2014年2月13日木曜日

Smallest but excellent performance

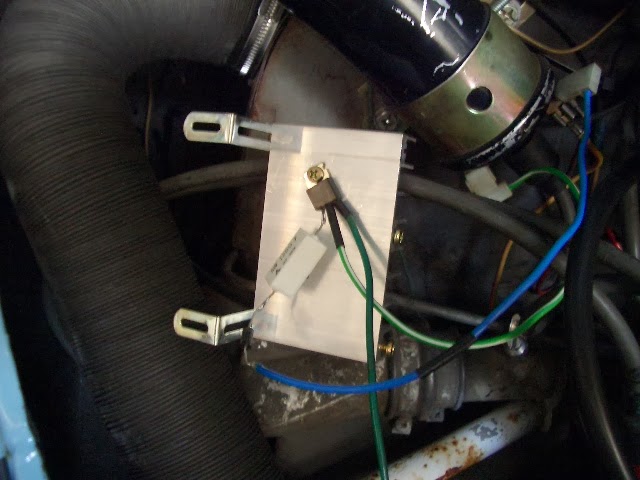

Crowded tube arrangement shows this Rooky 10 and OS 25LA has some unusual fuel supply system. Thank to YS fuel injection utilizing crank case primary compression pressure, very stable pressurized fuel supply is performed whatever attitude an airplane might take, such as rising up and down, spin or avalanche with no anxiety of power down nor motor stopping phenomena.

Rising up without any stall stress makes me possible to draw F3A-P15 pattern with this smallest Rooky10 trainer airplane? I wanna show the incredible scenery in front of the top flyers in the field, I would do that with confidence.

Also this over-powered Rooky10 would distribute a good opportunity to control this at the most adequate slow speed all through drawing the pattern. Only highest speed and lowest motor rotations were actually used over 30 years ago, but now the slow speed silent stunt is popular and prevailing, so the motor controlling technology is required in P15.

Hopeful motivation to be an applicant of the future contests comes up in my mind, I do not accept any situation like being guided by other persons especially by the production company engineer's one, I enjoy myself on my way just with surprising the factory engineers.

As an another story, OS 32F has fully disassembled and maintained with applying pressure nipple at the usual portion for preparing next step to burden in Rooky20, procedures would be exactly the same as Rooky10. As for my regretting matter, very important part of YS pressure regulator block is missing, so must I fabricate it by myself.

2014年2月11日火曜日

Leitz copy stand

Leitz copy stand lasts me as long as 40 years since silver salt period of time. This Leitz genuine product was supplied for Leicaflex users in the world at that time, but still now the accuracy of the main pole verticality and the stage flatness still remains through almost the half-century. I'm surprised to know the quality control of products produced by Ernst Leitz GmBH at that time. Not a few German Leitz products are still kept by myself, all of them still satisfy my difficult desire that hard to please. It goes without writing that the quality of their superb lenses at all, now Leica M lenses, a few Visoflex lenses and those of R ones, 2 M-Summicron 50, M-Summilux 50, M-Elmarit 90, Tele-Elmar 135, Elmar 135, Hektor 135, V-Macro Elmar 65, Summar 120, V-Telyt 180, V-Telyt 280, R-Macro Elmarit 60, R-Elmarit 135, R-Apo Summicron 180, R-Apo Telyt 280 and so on, they are all my favorite treasures.

Leitz copy stand lasts me as long as 40 years since silver salt period of time. This Leitz genuine product was supplied for Leicaflex users in the world at that time, but still now the accuracy of the main pole verticality and the stage flatness still remains through almost the half-century. I'm surprised to know the quality control of products produced by Ernst Leitz GmBH at that time. Not a few German Leitz products are still kept by myself, all of them still satisfy my difficult desire that hard to please. It goes without writing that the quality of their superb lenses at all, now Leica M lenses, a few Visoflex lenses and those of R ones, 2 M-Summicron 50, M-Summilux 50, M-Elmarit 90, Tele-Elmar 135, Elmar 135, Hektor 135, V-Macro Elmar 65, Summar 120, V-Telyt 180, V-Telyt 280, R-Macro Elmarit 60, R-Elmarit 135, R-Apo Summicron 180, R-Apo Telyt 280 and so on, they are all my favorite treasures.

2014年2月7日金曜日

Fuel supply

Not a few modifications were operated on Rookie 10 small trainer airplane yesterday. First of all, carburation has completely changed from normal aspiration to YS fuel pressure injection system, this is operated under a special device with diaphragm regulated and primary crank case pressure supplying into the fuel tank. Although, this one had been kept as one my juely for as long as 40 years. The carburetor should have fuel measuring system at idling speed, this is one of an indispensable requirement for YS fuel injection system. Trial running on a test bench showed reliable performance to be used on actual flight. The biggest advantage of well controlled fuel pressure system is that, operative condition does not change in any attitude of the airplane keeping decided amount of fuel injection, up & down, spin and avaranches with no anxiety of motor stop if the adjustment was adequate enough, but not difficult.

The injection system consist with a regulator, a pressure outlet nipple, an one way valve and micro mesh fuel strainer, very simple construction.

The regulator was positioned at just the nose gear portion outside because of shallow mounting space.

Over powered OS 25LA on Rooky10 is operated under a half throttle condition on ordinary flight and the full power is used only when it comes up while maneuver, so mechanical dumping stopper was invented on the transmitter stick portion, very simple as it is, so works well, the convenience of this modification would be realized if tried actually.

2014年2月5日水曜日

Peaky and difficult motor OS 25LA

It's snowing out side this early morning for the first time this year in spite of the beginning of the Spring on the diary yesterday. Cold weather would inhibit our customer to come to us today.

Started old hobby, Model airplane that is radio-controlled provides me many research projects, now I'm in the proposition of 2 cycle gas motor combustion. Reduction of compression ratio improves the condition with increasing chamber volume by applying 0,200mm thickness gaskets one by one, 2 sheets are not enough to come to plateau point, waiting next trial experiment. As my opinion, this OS 25LA gas motor has too high compression ratio to be used by some ordinary beginners or laymen, remembering my past experiences to come across with the scenery, no 25LA motor was not performed in it's best performance. In another words, a peaky and high compression gas motor has tendency to be difficult to be treated with relieve, because small change of circumstance invite nowhere fast. But, once the condition was fixed in the best one, this must show great and eye opening ultimately high performance. Even some manufacture production company engineer would stunned by the sight. Pulling out the surpassed performance is my dreamy intention!

Started old hobby, Model airplane that is radio-controlled provides me many research projects, now I'm in the proposition of 2 cycle gas motor combustion. Reduction of compression ratio improves the condition with increasing chamber volume by applying 0,200mm thickness gaskets one by one, 2 sheets are not enough to come to plateau point, waiting next trial experiment. As my opinion, this OS 25LA gas motor has too high compression ratio to be used by some ordinary beginners or laymen, remembering my past experiences to come across with the scenery, no 25LA motor was not performed in it's best performance. In another words, a peaky and high compression gas motor has tendency to be difficult to be treated with relieve, because small change of circumstance invite nowhere fast. But, once the condition was fixed in the best one, this must show great and eye opening ultimately high performance. Even some manufacture production company engineer would stunned by the sight. Pulling out the surpassed performance is my dreamy intention!

2014年2月3日月曜日

Consideration

Even a small model gas motor for beginners OS25LA gives me some precious opportunities to examine much deeper on the condition of combustion. In spite of additional 0,20mm thickness gasket application, still vanish production does not stop between piston and cylinder walls surfaces, especially on the portion between the side ports, note here, this economic motor has not main shnuerle ports but 2 side ports only, so this port designing must be a sensational affair, not a few researched must have been done by OS factory engineers?

But, found out I some description in Wikipedia about the uneven heat temp. distribution in the Shnuerle ported cylinder. Additional port forming there is in my imagination? Many description and articles are shown in the Web site, so, I have world wide opened biggest library here in front of my LCD with internet condition!

One of my old friend kindly gave me JR Explorer model for free of charge, this is an old new stock of his fabrications. So, the time would be relatively near future to come back this model airplane F3A field.

Too much care and kindness by circumstantial friend might make me spoilt child neglecting self efforts.

2014年2月1日土曜日

11AD Beetle repaired thorughly!

Removing spark plug #4, I found out that no sparking was triggered at all in spite of some fuel smell remained inside. My VW 11AD Super Beetle has not been serviced on the contact-breaker point gap as long as over 10,000km running. Before finding out the criminal of the affair this time, replacing procedures were done, a capacitor on the spark distributor, a spark coil and distributor assy. Even a trifle physical phenomena, too narrow contact point by melting down can cause fatal phenomena like this. Any way, replacing several keeping replacement parts had some good opportunity to be checked their healthy performances. Remember that Super Beetle I am keeping is basically different from recent automobile, fully mechanically controlled at all, so, periodical maintenance are indispensable at all. Now my babe has recovered original good condition. I don't know why my nose holes are so blacky after car maintenance?

登録:

コメント (Atom)